The community for Health and Safety Professionals. Check out today's discussions.

Welcome to Safety Knights!

Welcome to Safety Knights! The community for Health and Safety Professionals. Check out today's discussions.

The Safety Knights Podcast For Real World EHS Pros

Safety pros, we finally did it — Safety Knights has a podcast. ⚔️🎙️ The Safety Knights Podcast is our new way to bring the conversations from SafetyKnights.com straight into your truck, your walkaround, or your commute. It’s built for working EHS pros who live in the real world of: - Production schedules - Tight budgets - Culture challenges - Competing priorities on every shift Each episode is designed so you walk away with at least one practical idea you can try on your next shift, in your next toolbox talk, or at your next leadership meeting. What Is The Safety Knights Podcast? The Safety Knights Podcast is where EHS meets real life. Each episode digs into workplace safety, leadership, and innovation through candid conversations with safety managers, consultants, and industry veterans who’ve actually been there. Hosted by Zach Johnston, we: - Break down the challenges safety pros face today, from compliance headaches to culture shifts - Spotlight what’s working in the field - Share ideas you can adapt to your own site and teams Brought to you by the community behind SafetyKnights.com, the most active online hub for EHS professionals. Safety Knights mission: https://www.safetyknights.com/mission Who This Podcast Is For If any of this sounds like you, you’re in the right place: - You’re an EHS manager, coordinator, or director juggling compliance, culture, and capacity. - You’re a safety consultant trying to help clients move beyond “check the box” programs. - You’re new to safety and want to learn from people who’ve already taken the hits. - You’ve been in the field for years and want to hear what others are doing to keep safety fresh, relevant, and respected. We’re not here to lecture. We’re here to share real stories, real struggles, and real wins from people who understand the pressure of owning safety in a fast-moving environment. What You’ll Hear on Safety Knights Across episodes, you can expect conversations around: - Leadership & culture – how to influence without authority, get buy-in from operations, and turn safety from “have to” into “how we do things here.” - Practical tools – what’s working in training, communication, inspections, and reporting, beyond the buzzwords. - Lessons learned – honest breakdowns of mistakes, near misses, and hard-earned wins that changed how someone leads. - Career paths in EHS – the unconventional routes people take into safety, and what they wish they knew earlier. - Innovation in safety – new approaches, technology, and mindsets reshaping how we protect people and operations. If you’re the person everyone calls when something goes wrong, we want this podcast to be something you can lean on when you’re figuring out what to do next. How to Listen & Get Involved Here’s how you can support the show and get the most out of it: - Follow the podcast so you never miss a new episode. - Share episodes with your team, your safety committee, or that one coworker who’s just starting out in EHS. - Use episodes in training – play a segment during a safety meeting and discuss how it applies to your site. - Tell us what you want to hear – stories, topics, or guests you’d love us to bring on. Join the Safety Knights Community The Safety Knights Podcast is just one part of the bigger Safety Knights movement. If you haven’t already, dive into SafetyKnights.com for: - Community with other safety pros - Resources you can actually use in the field - Real-world safety conversations you won’t find in a manual Safety Knights community: https://www.safetyknights.com/join-us The quest for safer workplaces doesn’t happen in isolation. It happens when safety pros share what’s working, what isn’t, and what they’re still figuring out. Now we get to have those conversations together, one episode at a time. ⚔️ Where to Listen to the Safety Knights Podcast You can listen to The Safety Knights Podcast on: - RSS: https://api.riverside.fm/hosting/yug1MPTc.rss - iHeart: https://www.iheart.com/podcast/1333-safety-knights-podcast-309992139/ - Spotify: https://open.spotify.com/show/3ddh4fhhok5xGruKbilHLJ - YouTube: https://youtube.com/playlist?list=PL9pUeMnzaKuQy71a_hnAcY1JyzWRMFiJ7&si=4h1jlcuEbdup6KhN - Apple Podcasts: https://podcasts.apple.com/ph/podcast/safety-knights-podcast/id1852275325

Fractional Safety Work

Is there anyone here that does "Fractional" or "Outsourced" Safety work? I am in the beginning stages of starting a service to provide that kind of work, and am looking for advice that anyone is willing to give regarding what type of packages or services to offer, where one should land for pricing, pitfalls to avoid, areas to obtain insurance (and what the approximate cost might be). I attended Kamryn Johnson's webinar last week, and was thoroughly impressed with what is available with that network, but I want to get a couple clients under my belt before moving in that direction.

Clearing the Air: Common Gas Detection Myths, Pitfalls, and Challenges (WEBINAR)

Join us on February 10th at 10:00 AM CST for our free webinar titled "Clearing the Air: Common Gas Detection Myths, Pitfalls, and Real-World Challenges in Industrial Environments". 𝐖𝐞𝐛𝐢𝐧𝐚𝐫 𝐃𝐞𝐬𝐜𝐫𝐢𝐩𝐭𝐢𝐨𝐧 As portable gas detection technology advances, many workers develop a false sense of security, assuming better instruments automatically provide greater protection. In reality, a gas meter is only as effective as the user’s ability to interpret the data it provides. This webinar addresses common misconceptions surrounding various gas detection applications. Attendees will learn a risk-based approach to air monitoring that emphasizes hazard recognition, situational awareness, and critical thinking. The webinar explores how to identify potential “unknowns,” what those unknowns represent, and how to interpret readings in the context of chemical properties, process conditions, and changing environments. This webinar stresses the importance of empowering personnel with the competencies needed to adapt as conditions evolve, allowing attendees to gain a clearer understanding of why underestimating the “unknown” remains one of the most significant risks in industrial gas detection. 𝐑𝐞𝐠𝐢𝐬𝐭𝐫𝐚𝐭𝐢𝐨𝐧 𝐋𝐢𝐧𝐤 https://us06web.zoom.us/webinar/register/4017679901750/WN_CrRcnxvYTWWnzCkEydI_Sg

Workers Comp Training

Where's a good source for training and/or certification for workers comp? Considering filling in a knowledge gap for myself as a safety pro. I see a couple options online but I'm not sure what's good. Thanks and Happy New Year! Edit: preferably something California-specific. Thanks!

OSHA reporting question- Need advice asap!

We had a driver who was involved in an accident last Friday while on the road. He was taken to the hospital but at the time was not admitted as all they found was a bad leg laceration and lots of contusions. They did a CT at the time and everything came back okay and he was discharged with a splint on his leg due to torn muscles. I know this part makes it a recordable. Fast forward to last evening- His wife calls me and said he was taken to the ER due to complaints of eye pain and disorientation. She calls me later and states that the doctors at the ER determined he had a stroke and that they were admitting him. My question is, I am not sure that the stroke was determined to have happened during or before the time of the accident. Should I still call OSHA to report the hospital admission? Unfortunately, I have very little medical info other than what the wife is giving me. Our insurance company apparently is taking the holiday off as I am struggling to get anyone to call me back, which is not making me very happy at the moment.

AI in Safety?

Hi, my fellow Safety/IH professionals its no secret that AI is the non-stop topic as it was in the days of the internet. I am curious to know if/how everyone is using this tool? I enjoy using it for continuous learning. I am expanding on how I can review chemicals compatabilty and hazwaste determination. I'd love to hear from you.

Planning Safety Support Before the Project Starts

One thing I’ve learned after years in oil sands and industrial construction is this: The most effective safety support is brought in before a project hits peak pressure. When HSE is involved early, you see: • Better contractor alignment • Fewer last-minute workarounds • Stronger field ownership of risk • Less reactive firefighting Waiting until incidents, schedule compression, or turnover force the issue usually costs more, financially and culturally. For teams already looking ahead to 2026, early conversations around safety leadership, coverage planning, and field support can make a measurable difference once boots hit the ground. Curious how others here approach early-stage safety planning versus reactive deployment. What’s worked, and what hasn’t? #OilAndGas #ConstructionSafety

Job seeker

Hello everyone, unfortunately I get laid off on this season, now I'm looking for a spot, I know you need to trust in someone for putting into a such responsibility but I'm a reliable person. Looking for a bilingual safety tech, field safety, safety representative. Here is my LinkedIn profile: www.linkedin.com/in/ daniel-o-sotelo Thank you in advance.

??? for Safety Knights

I am about to go over 1500 in my "Influencer" total? What prize do I get? :)

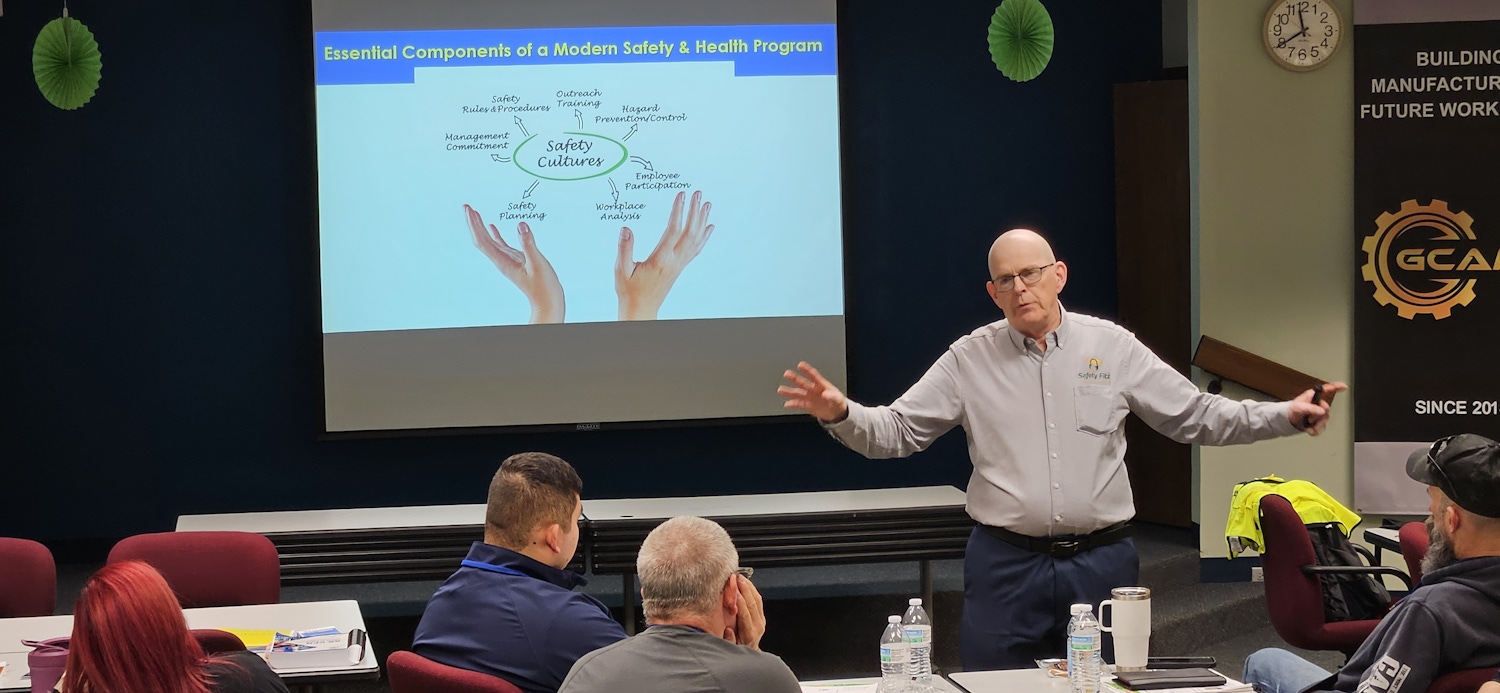

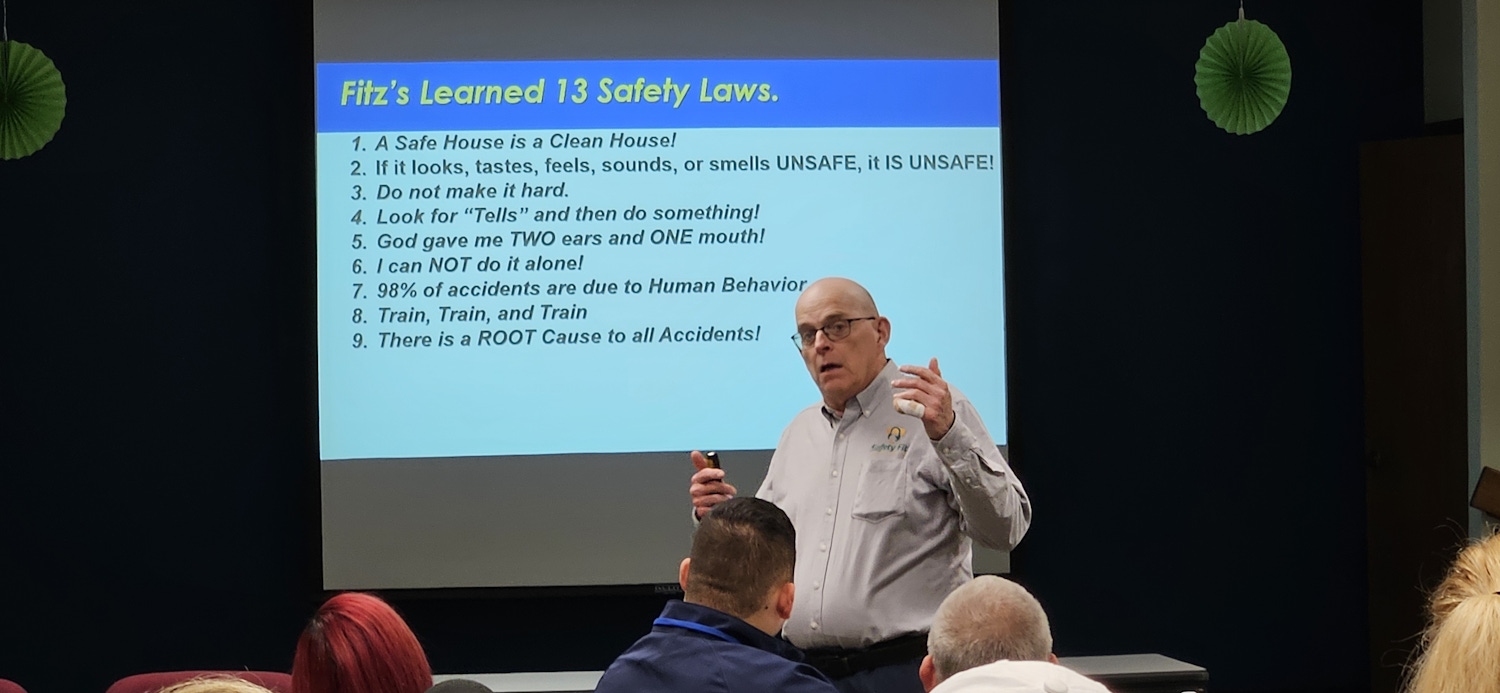

“Fitz’s Learned 13 Safety Laws.”

This is a picture of a General Industry OSHA 10-Hour course we did at the Valley Industrial Association in Geneva, Illinois last spring for Serve Pro. I did the course with co-instructor, and my pal, Jeff Bowers of Green Bay. We had fun and had great students! To stir up a little controversy and discussion, during the topic I always save for last, Safety Management, I put up a slide entitled, “Fitz’s Learned 13 Safety Laws.” In the picture Jeff took a picture as I was discussing #9. My training style is to be animated and create discussion. My list is based on my almost 50 years in this business. The next four (4) are: 10. At least 90% of all accidents might be the ultimate fault of Management! (Before you point a finger, remember you have three pointing back at you!). 11. PDCA (Plan Do Check Act) most things! 12. Make ALL Goals SMART (Specific, Measurable, Achievable or Attainable, & Time-bound)! 13. All & All, OSHA is a good thing, see the stats! ("Would your organization be “safe” with no OSHA?”) Bonus: A real Lean Safety Culture = Real Zero Injuries! If I can do it, you can for sure! Best Question in 50 Years: I was ever asked was by my old Foundry Senior Foreman, Big Johnny, while I was a new foundry supervisor, especially when we had a bad accident and/or things looked dire, “Well Fitz, we got the tail wagging the dog again?” I always wanted to crack a smile at that, but sometimes he would be yelling it so loud I would really have to control myself! The best safety training quote in 50 years comes again from Big Johnny: "Fitz, even if it wasn't your fault that Joe got hurt, however, it might have been. But it is always, always your responsibility!" Now get me that accident report! B4YGH (Before You Go Home)!” Johnny frequently wrote "B4YGH" in his orders to us. What do you think? Do you disagree with any or have any additions?

Scissor lift written program

Would anyone have a scissor lift written program (preferably from a general industry setting) they would be willing to share? I am not wanting to copy it, necessarily, but to make sure I am including things I should be including. We have scaffolding also, so I'm guessing it could be included in the policy as well considering it all falls under the same standard? We have had a written policy before but I'm going through all of our policies and programs to review for annual and revise if needed.

Cold Stress/ Winter Weather training

Does anyone have a good winter weather/ cold stress training PowerPoint that they use that I could steal :)

Heavy Equipment Inspection Books - Bilingual

Has anyone found a vendor for bilingual English and Spanish equipment inspection books?

EH&S Consultants

As someone who has had to hire dozens of EH&S consultants over the years, from training, to policy procedure development, to ISO support, etc. I am curious for others; What are the most important aspects to you, when you are hiring a consultant? Let me know below, and feel free to comment your thoughts.

Camera recommendations

Anyone have any PIT camera recommendations? I already saw a demo with OneTrack.Ai. I want visibility into the operator's area not just around the equipment.

Predictive AI vision monitoring software

Looking for anyone using video based monitoring software like Intenseye, Voxel, Protex AI, etc. Trying to compare them & hoping for feedback.

Best Practice for Work at Height + Rescue Standards? Need Guidance

Hi everyone, I’d appreciate your insights on best practices for work at height and rescue planning. Currently, our setup is: We hire an IRATA Level 3 technician to design the work station, supervise the job, and act as the primary rescue lead. We follow an internal guideline that requires the rescue team to initiate rescue within 15 minutes. Because of this, we don’t rely on external emergency services (e.g., 911) as the primary rescue method — only as a backup. My questions are: 1. Is this level of strictness normal or excessive? 2. What are the accepted minimum standards or safe benchmarks for work-at-height rescue response time? 3. Do most companies use internal trained rescue teams, or do they rely more on external emergency services? 4. Are there recognized standards (OSHA, IRATA, SPRAT, EN standards, etc.) that outline what “reasonable” rescue preparedness should look like? Any advice, experience, or references would be very helpful. Thank you!

Safety Gear/PPE Nerd

Do any other Safety Knights completely nerd out over PPE or safety gear? I'm sure most of us do a little bit...but man, I really love it when I get to wear my vest and hard hat, etc. I'm such a nerd about it, my favorite color is hi-viz yellow with reflective stripes. I'm always looking for something to add into my rotation of vests, hard hats, gloves, safety glasses, etc. When I watch movies and TV and see PPE, I'm trying to identify the brand/style the actor is wearing and if they are using it correctly. Back when I was a firefighter, I would critique movies for bunker gear failures. Please tell me there's others out there like me? lol

Creative Warehouse Storage Idea Vetting

Our warehouse team has been tasked with taking greater advantage of vertical space while not occupying space that is already set aside for more production. Therefore, I'm fielding some interesting questions and I'm hoping to get some feedback to validate my thinking. 1. Storing palletized materials above wall battery chargers. I'm planning to say No to this due to the proximity to combustible material. The pallets will contain paper packaging products and will be shrink-wrapped on wooden pallets. 2. Building racking above a walkway that would allow people/materials to pass under. This one I'm borderline on, since the same idea is used in places like NYC where there are pedestrian paths underneath scaffolding structures. - There would be a solid surface for the materials to rest on (not wire grating or open storage). - The racking would be two pallets deep, using a reach truck to access and remove. I haven't found a regulation that would prohibit this type of setup, and they haven't yet reached out to the vendor to see if this type of design is even structurally possible. Our facility also has AMR Robots where if we can't allow people through the path then we could just allow the robots. I'm having trouble uploading photos but will try to do so in the comments. Also, feel free to tell me I'm an idiot for entertaining these LOL.

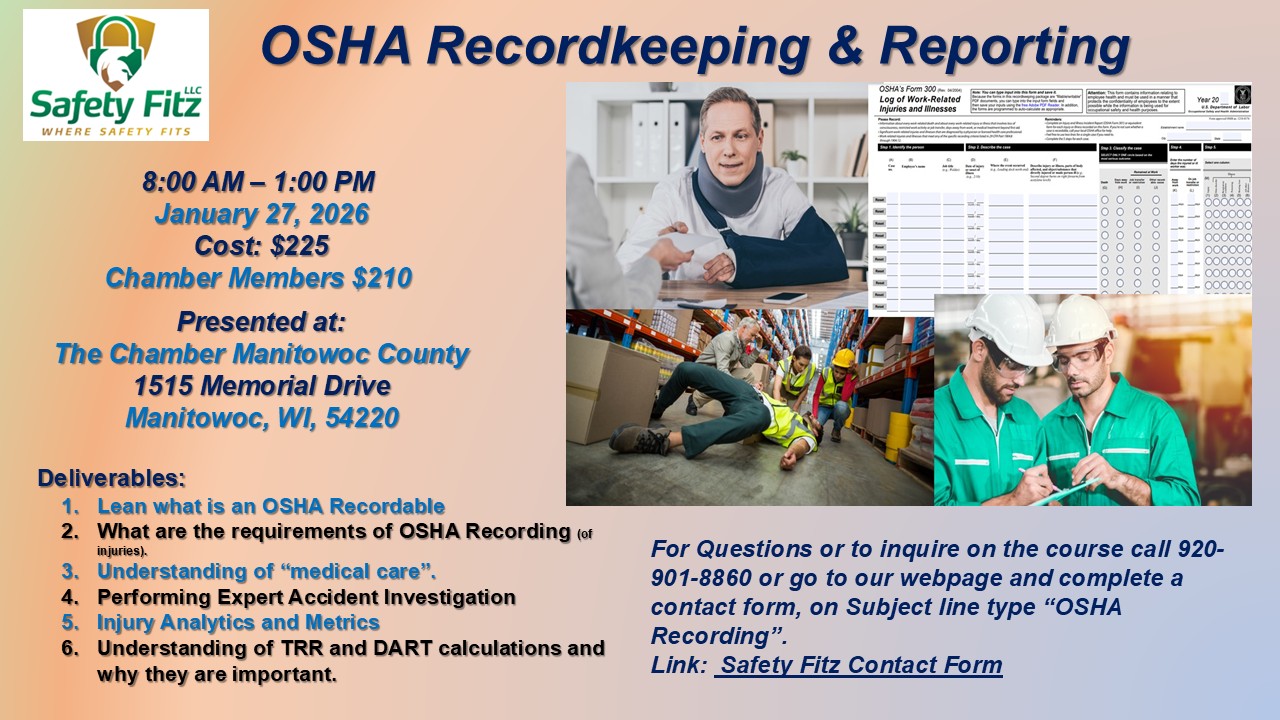

OSHA Recordkeeping & Reporting - If you are located in Northeastern Wisconsin!

From an expert who had been doing it for almost 50 years!

CIT Study Materials

Which entity have you all 1) used 2) heard of and 3) recommend for studying of the CIT?